-

Home

-

Jamo Solutions LTD

-

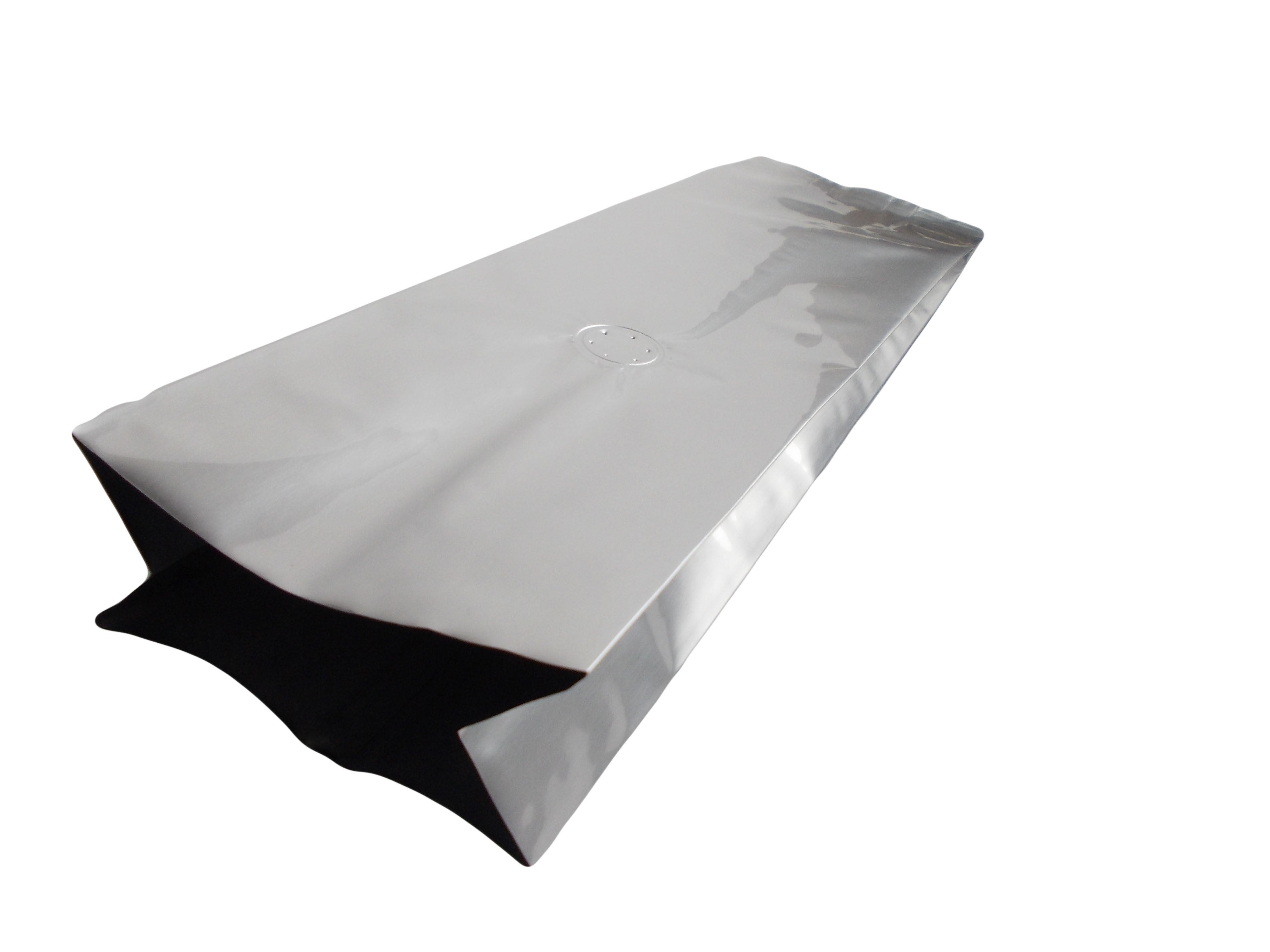

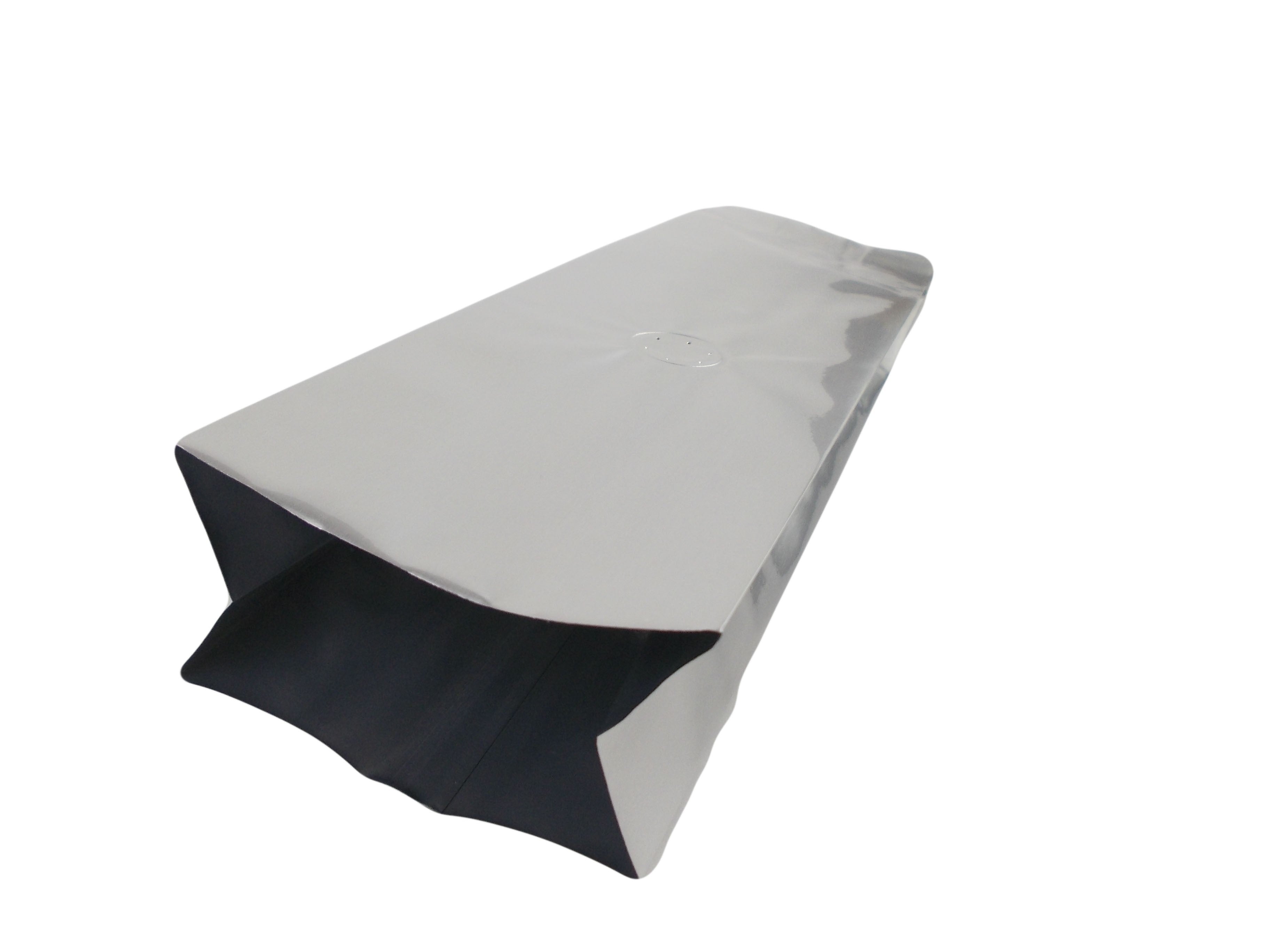

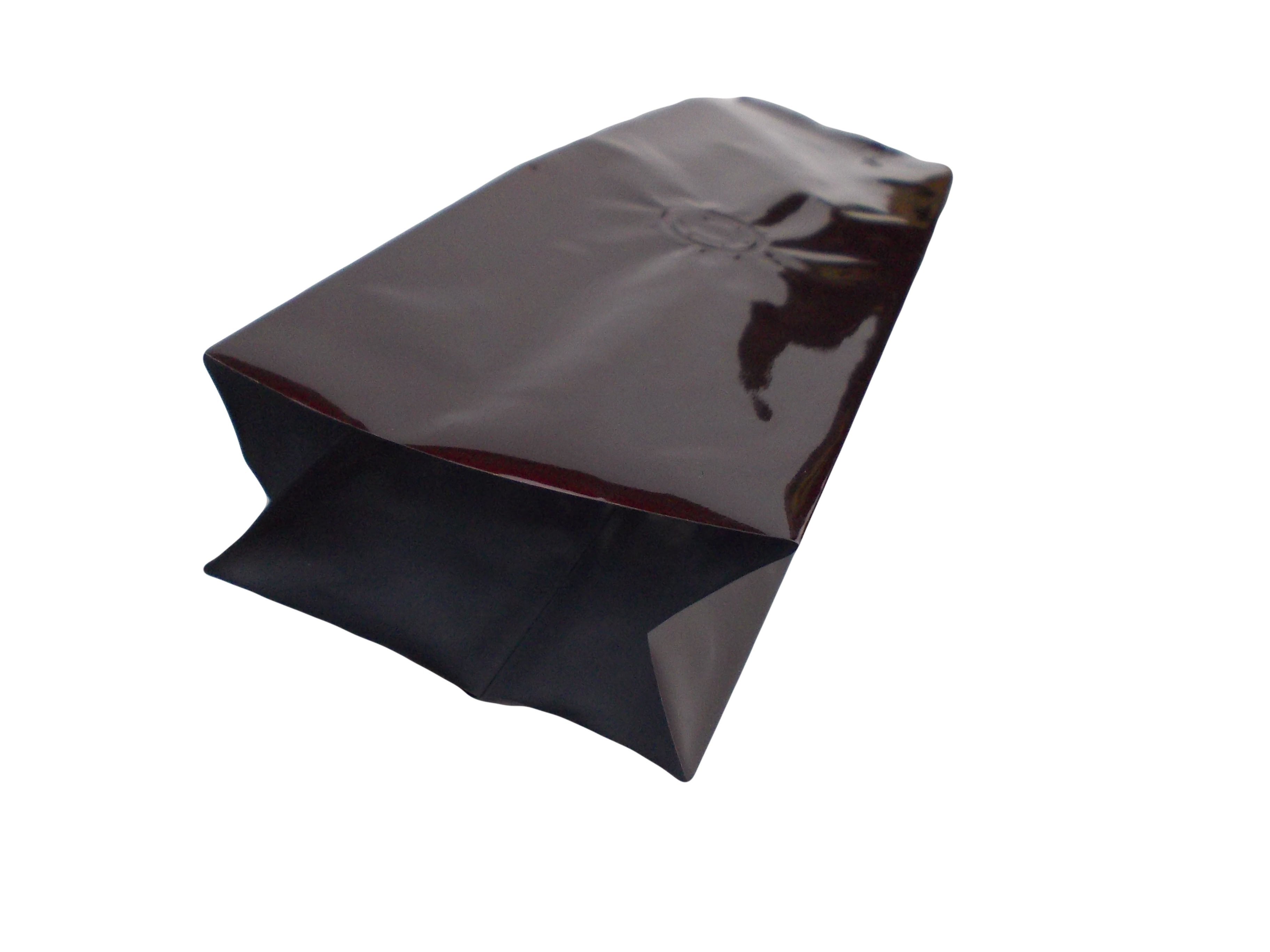

Internal Valve Side Gusset Pouch

Internal Valve Side Gusset Pouch

Product details

| S |

Bag's specification |

||

|

Type: SIDE GUSSET |

|||

| SIZE | 50 | 100 | 250 | 500 | 1000 | TOLERANCE** | UNIT |

| WIDTH (A) | 65 | 80 | 80 | 100 | 135 | +/- 2 | mm |

| DEPTH(G) | 35 | 35 | 45 | 55 | 70 | +/- 2 | mm |

| HEIGHT (H) | 190 | 210 | 280 | 330 | 360 | +/- 2 | mm |

| WIDTH OF BOTTOM SEAL (Zd)* | 6 | 6 | 6 | 6 | 6 | +/- 2 | mm |

| WIDTH OF BACK SEAL (Zt) | 25 | 30 | 30 | 35 | 35 | +/- 2 | mm |

| OUTLINE | |||||||

|

|||||||

| ADDITIONAL REMARKS |

*Each seal is considered separately. **Due to a mass production, admissible amount of bags that don`t meet specified requirements may be up to 2% of delivery. |

||||||

Advanced side gusset pouches with internal degassing valve technology for optimal coffee packaging and freshness preservation. Our innovative valve system allows CO2 release while preventing oxygen ingress, maintaining peak coffee freshness and flavour. Perfect for coffee roasters and specialty food producers requiring professional-grade packaging that preserves product quality and extends shelf life.

Fabric: Polyethylene terephthalate / Aluminium / Polyethylene

Thickness: 250g 100 microns, 500g 100 microns, 1000g 100 microns

Why Customers Love Our Internal Valve Side Gusset Pouch

• Internal degassing valve technology

• CO2 release with oxygen barrier

• Professional coffee packaging

• Extended freshness preservation

• Advanced barrier protection

These Side Gusset Pouches with Internal Valve are a customer favourite for packaging

fresh roasted coffee beans, specialty coffee packaging, premium coffee blends, ground coffee and teas

Internal valve uses:

- releases excess gases from inside the pouch

- protects contents from oxygen exposure

- preserves the product’s original flavour and aroma for longer

How does the valve work?

The valve is made up of a body and a membrane. Even the slightest overpressure inside the pouch causes the membrane to bulge. As the pressure increases, the membrane lifts at one point, creating a small channel through which the gases can escape. Once the pressure has been released and equalised, the valve closes, and the membrane returns to its original position against the valve body. This process reliably protects the contents from external oxidation.

Important! Choosing the right pouch size

Different products take up different amounts of space, even if they weigh the same. If you’re not sure which size you need, just tell us about your product and we’ll help you choose the right pouch.

Food Grade

Biodegradable pouches are made from natural, GMO-free materials, which makes them a safe and reliable choice for organic products and brands that care about clean ingredients and environmentally responsible packaging.

Heat-Sealable

Heat sealable and produced in accordance with strict European Union standards, all our packaging solutions are designed to ensure full regulatory compliance, high safety levels, and consistent, reliable performance throughout everyday use.

GMO-free

Biodegradable pouches are made of material that is not only natural but also GMO-free. This feature makes the biodegradable bags to be perfect for organic products.

3 Layers

Our triple-layered pouches provide superior protection and quality, ideal for products needing extra shielding. Choose our EVOH-layered pouches for extremely low oxygen permeability.

Flat Pouch

Our triple-layered pouches provide superior protection and quality, ideal for products needing extra shielding. Choose our EVOH-layered pouches for extremely low oxygen permeability.

EU Compliant

All our packaging solutions strictly adhere to European Union standards, ensuring compliance and safety in every product.

Custom Pouches Printing Options

Custom Printed Pouches (Post-Production Printing):

✔ Fast printing on ready-made pouches

✔ Minimum order: just 100 pcs

✔ Ready within 7 days (express option available)

✔ Artwork must be adapted to our print specs & template

Fully Customised Pouches (Pre-Production Printing):

✔ Choose your design, material, size & finishes

✔ Full-coverage, edge-to-edge print

✔ Minimum order: 1,000 pcs (not 10,000!)

✔ Lead time: only 3–5 weeks

✔ Artwork must be adapted to our print specs & template

(30-100k pieces)

We do our best to dispatch all orders as quickly as possible - usually within 1-3 days within UK Mainland and 2-3 days for deliveries to the EU.

The exact shipping cost and estimated delivery time are shown at checkout once you enter your address. Please note that while we control the dispatch time, the final delivery time depends on the courier, so the provided time frame is an estimate.

If you wish to return your purchase, we’re happy to offer a refund or exchange - as long as the items are unused, in their original packaging, and in perfect, fully resalable condition.

You have 28 days from the delivery date to return your order.

If the goods are faulty or incorrect, you need to tell us you don't want the products within 14 days of receiving them. Once we confirm your return, you’ll have another 14 days to send the products back.

For full details, please see our Delivery and Returns

Custom-made pouches

Your packaging, your style. Design your custom-made pouches – choose the material, size, features (e.g. zip lock, tear notch, or custom-shaped window) & finish. We’ll take care of every detail to make your pouch look exactly the way you want – ensuring your brand stands out.